test headline

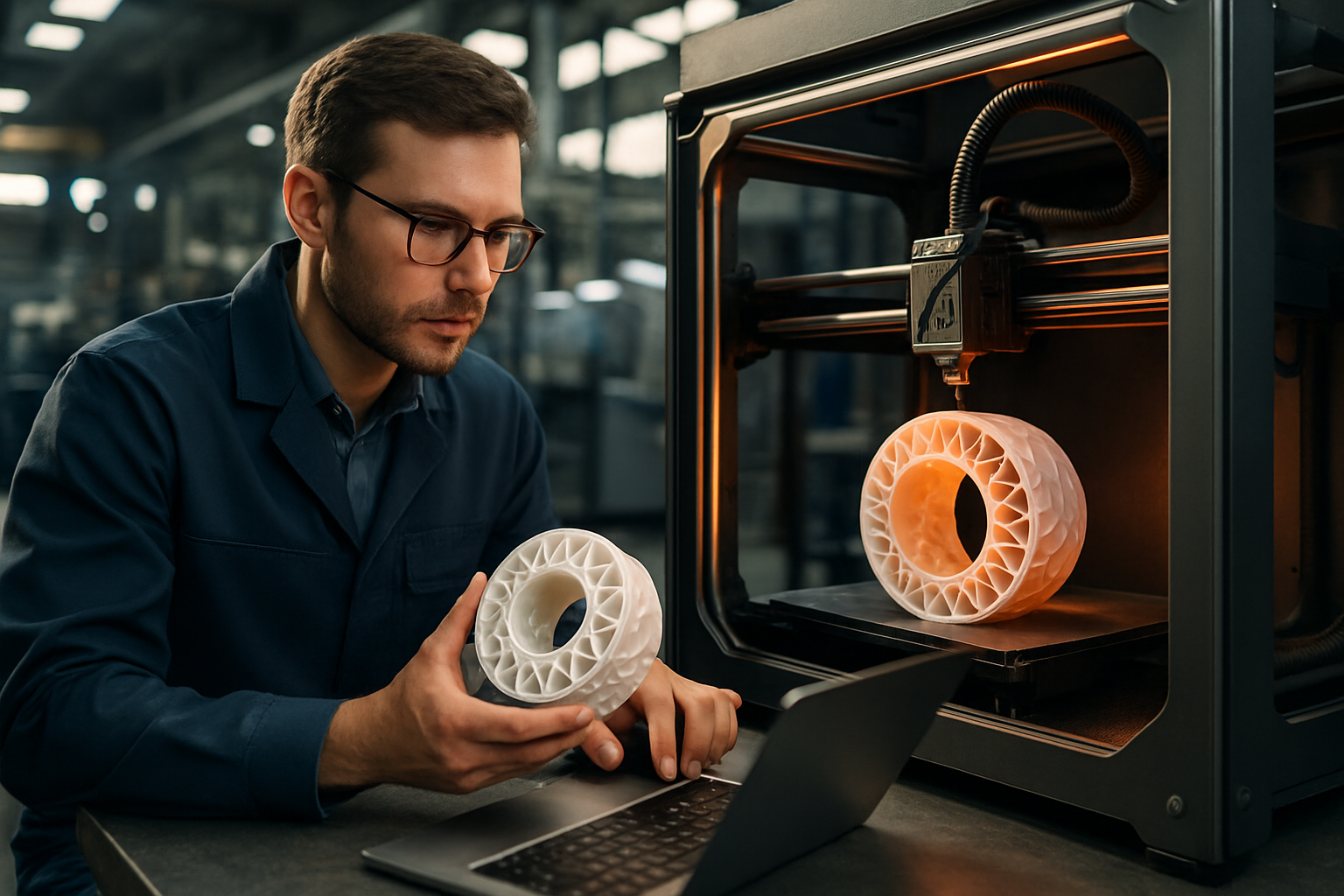

3D printing technology has revolutionized manufacturing, prototyping, and creative industries. This innovative process allows for the creation of three-dimensional objects from digital designs, layer by layer. As 3D printers become more accessible and affordable, they're finding their way into homes, schools, and businesses across the United States. Let's explore the world of 3D printing and how it's shaping our generation's approach to creation and problem-solving.

What exactly is 3D printing and how does it work?

3D printing, also known as additive manufacturing, is a process of creating physical objects from digital files. It works by laying down successive layers of material until the entire object is formed. The most common materials used in 3D printing are plastics, but metals, ceramics, and even food-safe materials can be used depending on the printer and application.

The process begins with a 3D model, typically created using computer-aided design (CAD) software. This model is then sliced into thin layers by specialized software, which sends instructions to the 3D printer. The printer then builds the object layer by layer, fusing each new layer to the previous one until the final product emerges.

What are the main types of 3D printers available today?

There are several types of 3D printers, each using different technologies and suitable for various applications:

-

Fused Deposition Modeling (FDM): The most common and affordable type, FDM printers melt plastic filament and extrude it layer by layer.

-

Stereolithography (SLA): These printers use a laser to cure liquid resin into solid plastic, producing high-resolution objects.

-

Selective Laser Sintering (SLS): SLS printers use a laser to sinter powdered materials, often used for industrial applications.

-

Digital Light Processing (DLP): Similar to SLA, but using a digital light projector screen to cure resin.

-

Metal 3D Printing: Various methods exist for printing metal objects, including Direct Metal Laser Sintering (DMLS) and Electron Beam Melting (EBM).

How is 3D printing transforming industries and education?

3D printing is making significant impacts across various sectors. In manufacturing, it allows for rapid prototyping and the production of complex parts that would be difficult or impossible to create with traditional methods. The medical field uses 3D printing to create custom prosthetics, dental implants, and even replicate organs for surgical planning.

In education, 3D printers are being used to enhance STEM learning. Students can design and print their own creations, bringing abstract concepts to life and fostering creativity and problem-solving skills. This hands-on experience with cutting-edge technology prepares students for future careers in engineering, design, and manufacturing.

What are the environmental implications of 3D printing?

The environmental impact of 3D printing is a topic of ongoing research and debate. On one hand, 3D printing can reduce waste by creating objects with minimal material and allowing for on-demand production, potentially reducing overproduction and inventory. It can also lead to more efficient designs that use less material and energy.

However, the most common 3D printing materials are plastics, which raise concerns about sustainability and biodegradability. Additionally, the energy consumption of 3D printers and the potential for increased production of small plastic items could have negative environmental effects. As the technology evolves, more eco-friendly materials and energy-efficient printers are being developed to address these concerns.

What unique applications of 3D printing are emerging in the United States?

In the United States, 3D printing is finding innovative applications across various fields. In architecture, firms are using large-scale 3D printers to construct homes more quickly and affordably, potentially addressing housing shortages. The fashion industry is experimenting with 3D-printed clothing and accessories, pushing the boundaries of design and customization.

NASA is exploring the use of 3D printing for space exploration, including the potential to print tools and spare parts on Mars. In the culinary world, chefs are using specialized 3D printers to create intricate food designs and customized confections. These diverse applications showcase how 3D printing is fostering creativity and solving problems in uniquely American industries.

How much do 3D printers cost, and what options are available for consumers?

The cost of 3D printers varies widely depending on the type, size, and capabilities of the machine. For consumers and small businesses, there are options available at different price points:

| Printer Type | Provider | Cost Estimation |

|---|---|---|

| Entry-level FDM | Creality Ender 3 | $200 - $300 |

| Mid-range FDM | Prusa i3 MK3S+ | $750 - $1000 |

| Desktop SLA | Formlabs Form 3 | $3500 - $4000 |

| Professional FDM | Ultimaker S5 | $5000 - $6000 |

| Industrial SLS | EOS P396 | $250,000+ |

Prices, rates, or cost estimates mentioned in this article are based on the latest available information but may change over time. Independent research is advised before making financial decisions.

Entry-level FDM printers are now affordable for home use, while more advanced models cater to professionals and businesses. The choice depends on the intended use, required print quality, and budget. Many consumers start with a basic FDM printer to learn the technology before investing in more advanced models.

In conclusion, 3D printing is a versatile technology that’s reshaping how we approach design, manufacturing, and problem-solving. From affordable home printers to industrial-scale machines, 3D printing offers opportunities for innovation across generations and industries. As the technology continues to evolve, we can expect to see even more creative applications and advancements in the years to come.